Yongjian Machinery and Yinjinda Join Forces, Domestic Biaxial Stretching Equipment Leads New Breakthrough in BOPETG Industry

2025-06-30

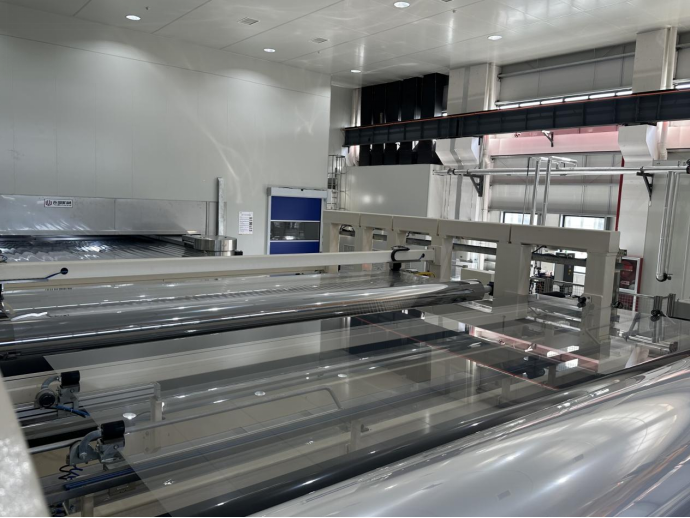

Amid the accelerating upgrades in the biaxially oriented polyester film (BOPETG) industry, domestic equipment is demonstrating strong competitiveness. Yinjinda Group, a leading enterprise in China's high-performance eco-friendly film materials, has formed a strategic partnership with Yongjian Machinery, marking a significant breakthrough for domestic biaxial stretching equipment in the high-value-added film sector. On June 1, their jointly developed high-end BOPETG production line successfully commenced operations, achieving stable production on the same day of material feeding and film output.

Core Advantages: From "Import Substitution" to "Performance Leadership"

➪ General Manager Wu of Yinjinda (Shanghai) New Materials stated:

"Choosing Yongjian Machinery was a decision made after rigorous evaluation. Their three core strengths—synchronous stretching technology, energy consumption control, and customized services—fully align with our pursuit of 'green intelligent manufacturing.'"The production line has delivered outstanding performance since its launch, meeting all expected targets.

➪ General Manager Du Yongsheng of Yongjian Machinery emphasized:

"Domestic equipment has evolved from 'import substitution' to 'performance leadership':

·Prices lower than imported brands

·Delivery cycles short

·Key parameters such as thickness uniformity and energy efficiency rival those of top international brands."

A New Industry Benchmark: Customized Development of Specialty BOPETG Films

➪ Designed specifically for high-performance demands, General Manager Wu outlined Yinjinda’s three future development directions:

1.Technological Breakthroughs: Optical/medical-grade high-end applications

2.Green Upgrades: Establishing a circular economy system

3.Intelligent Transformation: Developing next-generation smart production lines

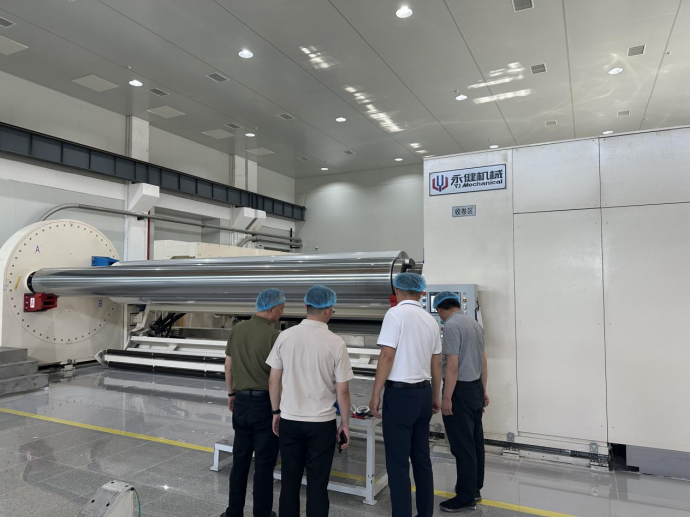

Efficient Collaboration Model Earns Mutual Recognition

➪ Yinjinda's team noted:

"From installation to mass production in just three months, Yongjian Machinery’s 24/7 response mechanism ensured smooth and efficient operations."

➪ Yongjian Machinery's team added:

"The client’s professional cooperation created optimal conditions for implementation—a win-win model worth promoting."

This collaboration not only showcases the strength of domestic equipment but also heralds the arrival of a new era of synergistic innovation between "equipment and materials" in China’s film industry.

Copyright© 2025 Shandong Yongjian Machinery Co., Ltd. Powered by www.300.cn

Copyright© 2025 Shandong Yongjian Machinery Co., Ltd.

This website already supports IPV6 SEO

sales@yjmachinery.com

sales@yjmachinery.com

+86 17616798109

+86 17616798109