Crafting Extraordinary Biaxial Stretching Films: Focusing on Specialized Applications, Closed-Loop Recycling & Lifelong Performance - K 2025 | Yongjian Machinery | Highlight Exhibition

2025-09-23

|

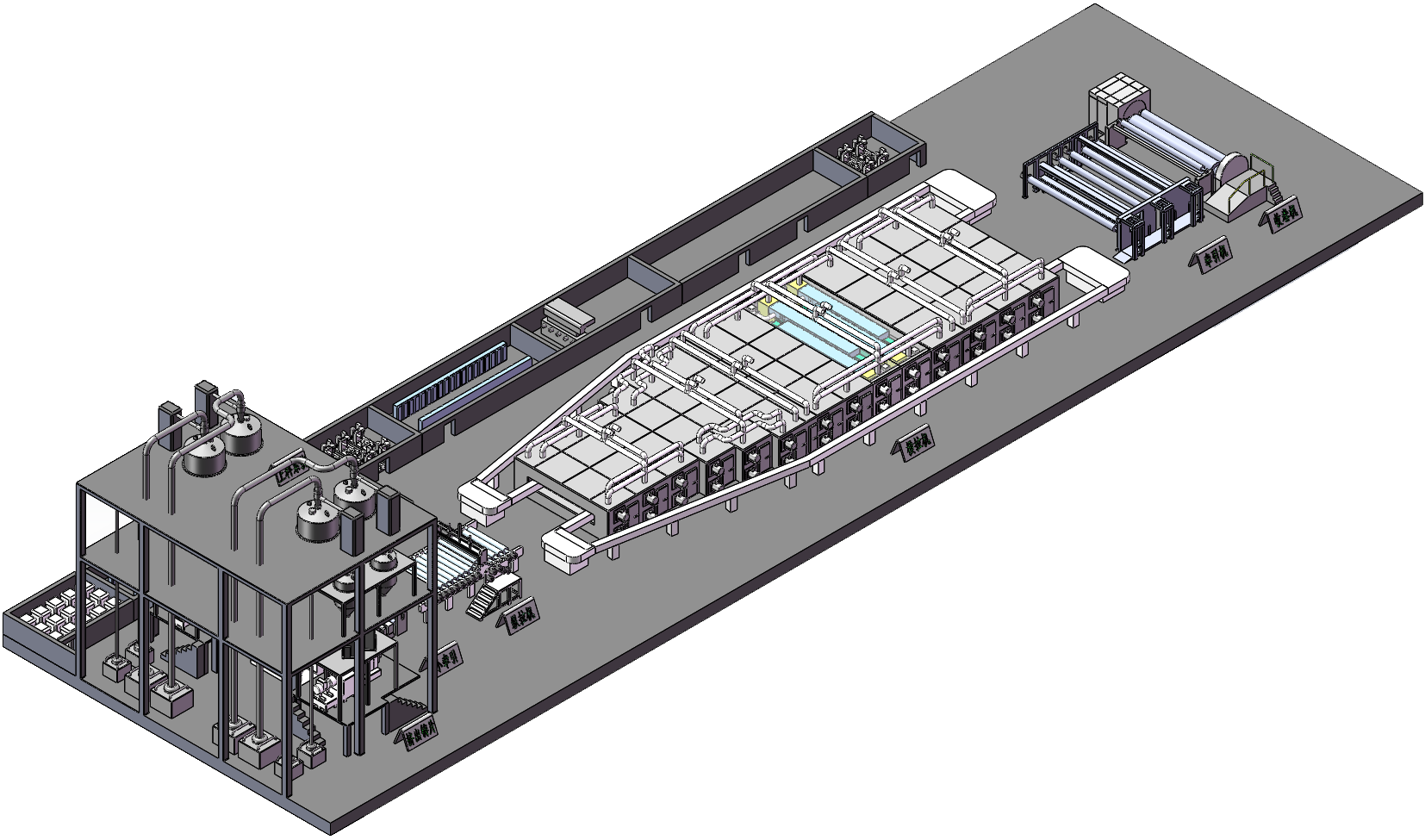

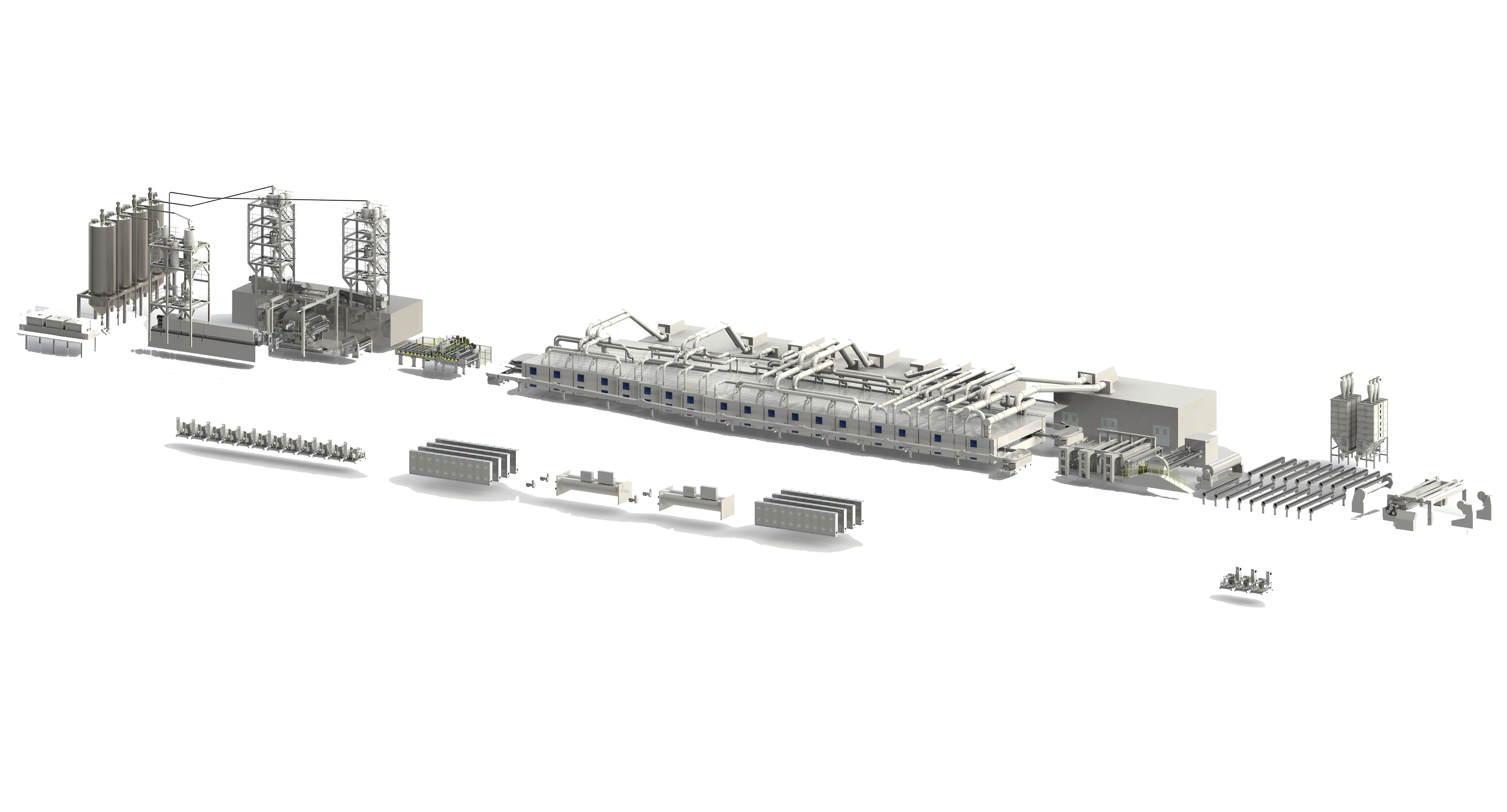

⭐【The Precision Embodiment of Cutting-Edge Materials, Leading the New Trend of Intelligent Manufacturing】⭐

|

|

|

⏺【The Path to Circularity: Enabling Sustainable Manufacturing】⏸

|

|

☄【Empowering Production Line Renewal, Ensuring Sustainable Operation】☄

|

|

✨ We sincerely invite you once again:

❣ Visit us at Hall 13, Booth D21 at K 2025 in Germany!

Let’s explore the limitless possibilities of intelligent manufacturing together!

https://www.kujiale.com/pub/render/pano/custom/tour/3FO4K6THWOGQ

(Click this link to visit our virtual booth)

sales@yjmachinery.com

sales@yjmachinery.com

+86 17616798109

+86 17616798109